HIGHWAYS, RAILWAYS AND ANIMAL FENCE SYSTEMOVERVIEW: |

|

USE: SIZE: CLADDING:

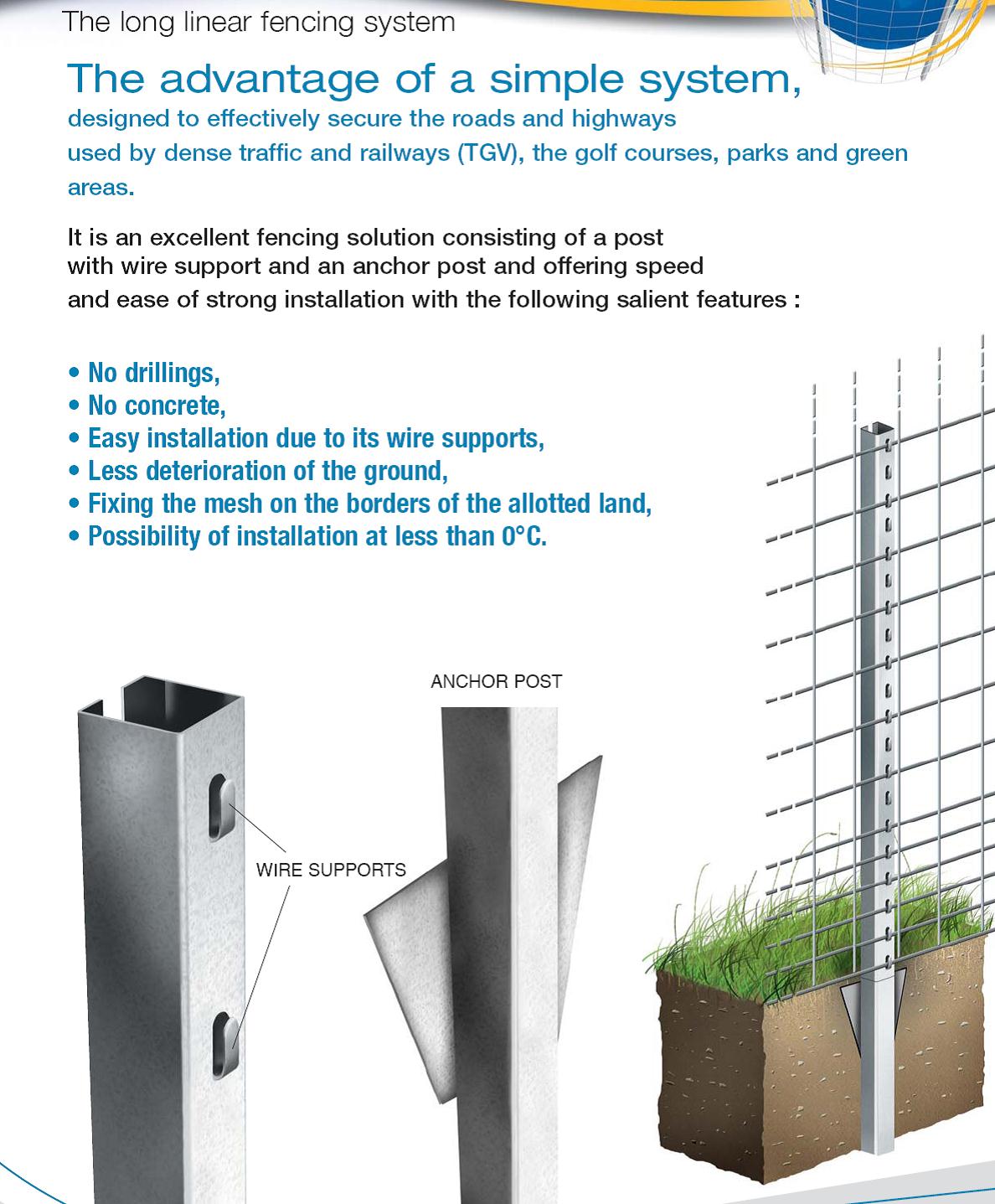

a) Plain or barbed horizontal wires POSTS: The post system is the unique feature. A ground socket with a flat thrust plate welded on is driven into the ground at 3m to 4m centres by pneumatic hammer and the post is dropped in until it engages in two flanges that make it non-removable. The posts made from high quality steel, cold rolled to form 50mm x 50mm nominal square section with clipping points of 100mm centres. Posts stand up to 2.50m above ground. Ground sockets 1m long driven into ground, 600mm and 400mm protruding, with tops of thrust plate at finished ground level. Longer sockets available for soft terrain. Main post then attached. End, intermediate and corner straining posts available with raking 45° struts and additional back struts for corners fixed with 600 mm long heavy pins. Straining of the cladding, if required, is usually devised by the installer company i.e. radiusseurs, hook bolts, eyebolts, barrel bolts, ratchet strainers, flat bars etc. OPTIONAL FIEATURES: 1 Posts with 45° cranked extensions for barbed wire. 2 Extension brackets to raise the height of existing fences 3 Ground sockets with baseplate with 4 fixing points for bolting to existing flat, hard surfaces. FINISH: INSTALLATION: Up to 1.50km of this fence can be installed on normal ground in a single day with a 10 to 12 man team and plant.  Fast and easy installation to European highways  1,000’s of km supplied to the European rail network  Tractor mounted quickfencer decoiling system.  |